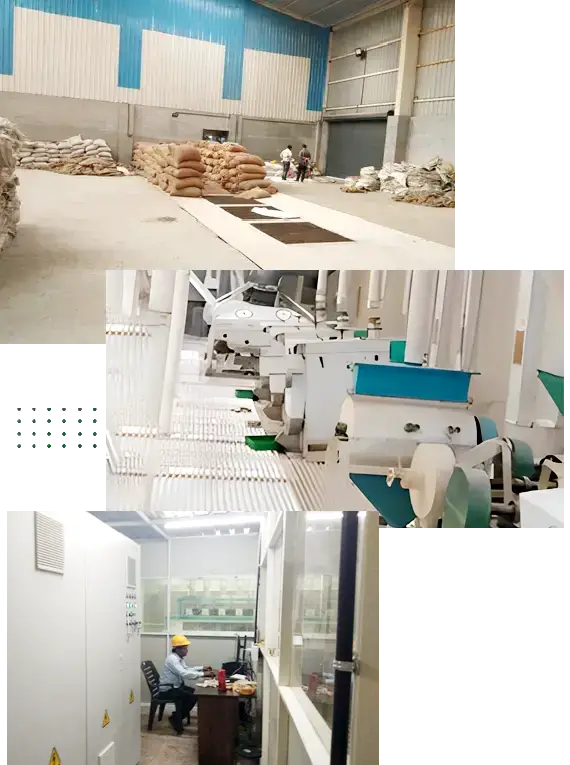

The Milling Facility

A fully automated milling unit set up on 2 acres of land is a state-of-the-art facility for processing and packaging raw materials into finished products. With the use of gas-powered dryers, this facility ensures that there is no cross-contamination of impurities, which was a common issue with the old-school method of drying in courtyards.

The milling process is carried out in a closed environment, which further reduces the risk of contamination and ensures that the final product is of high quality. The milling facility itself is spread out over 15,000 sq. ft., providing ample space for the milling process to take place. Additionally, there is a raw material godown spread out over 5,000 sq. ft., which is used for storing the raw materials before they are processed. The finished material godown is spread out over another 5000 sq.ft. and is used to stack packed finished material ready to be dispatched to customers.

Overall, this setup is highly efficient and ensures that the milling process is carried out in a safe, closed, and controlled environment, which helps to maintain the quality, hygiene, and purity of the final product. Being the first facility in India to use gas-powered dryers is a significant achievement, enabling contamination-free food products, and representing a significant step forward in the milling industry in India.